Product Description

Product Description

| BASIC INFORMATION | |

| ITEM | NH Coupling |

| SIZE | 1.5″/2″/2.5″/3″/4″/5″/6″ |

| TECH. | Forged |

| W.PRESSURE | 2.5MPa(365PSI) |

| T. PRESSURE | 4.0MPa(580PSI) |

| MATERIAL | Aluminum Alloy |

| COLOUR | Sliver/Golden/Black/Customized |

| BRAND | TOKAI XIHU (WEST LAKE) DIS.TA/ OEM |

| SERVICE | OEM/ODM |

| FINISH | Anodizing/Hard Anodizing |

| HISTORY | 22years manufacturing experiences of fire fighting equipments |

| HS CODE | 8481809000 |

Detailed Photos

Packaging & Shipping

Company Profile

TOKAI XIHU (WEST LAKE) DIS.TA is specialized in designing and manufacturing fire fighting equipment mainly including fire hose couplings and fittings, nozzles, fire vehicle equipment and fire hose crimping machine. We employed CNC lathe, CNC turning composite center, CNC machining center, forging equipment, heat treating facility and the latest testing equipment to improve dimensional accuracy and quality management. Given more than 20years of development, we not only have broadened the company’s product line but also have developed our capability to meet our customers’ specific requirements and offer products or services that give added value. We have passed the ISO9001:2015 Quality Management System Evaluation and got the certification of CCC. At present, our products are mainly exported to Japan, the United States, Germany, South Korea, ZheJiang , Indonesia, Thailand, Dubai and other global markets, which are highly praised by customers. In domestic market, high-end fire hose factories, fire vehicle manufacturers and the national fire team are our important strategic partners.

Adhere to the idea of forward-looking innovation, outstanding excellence, continuous improvement and sustainable management, we provide best service to clients. The most important purpose of our company is to ensure that our products have excellent quality, on time delivery with competitive price. We will take it as our duty to create most valuable brand in high-end fire hose couplings. Let’s join hands and work together to build a prosperous future!

Certifications

Our Advantages

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | CCCF, CCC, ISO9001 |

|---|---|

| Surface Treatment: | Anodizing/Hard Anodizing |

| Material: | Aluminum Alloy |

| Tech.: | Forged |

| W.Pressure: | 2.5MPa(365psi) |

| Color: | Silver/Golden/Black |

| Samples: |

US$ 25/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

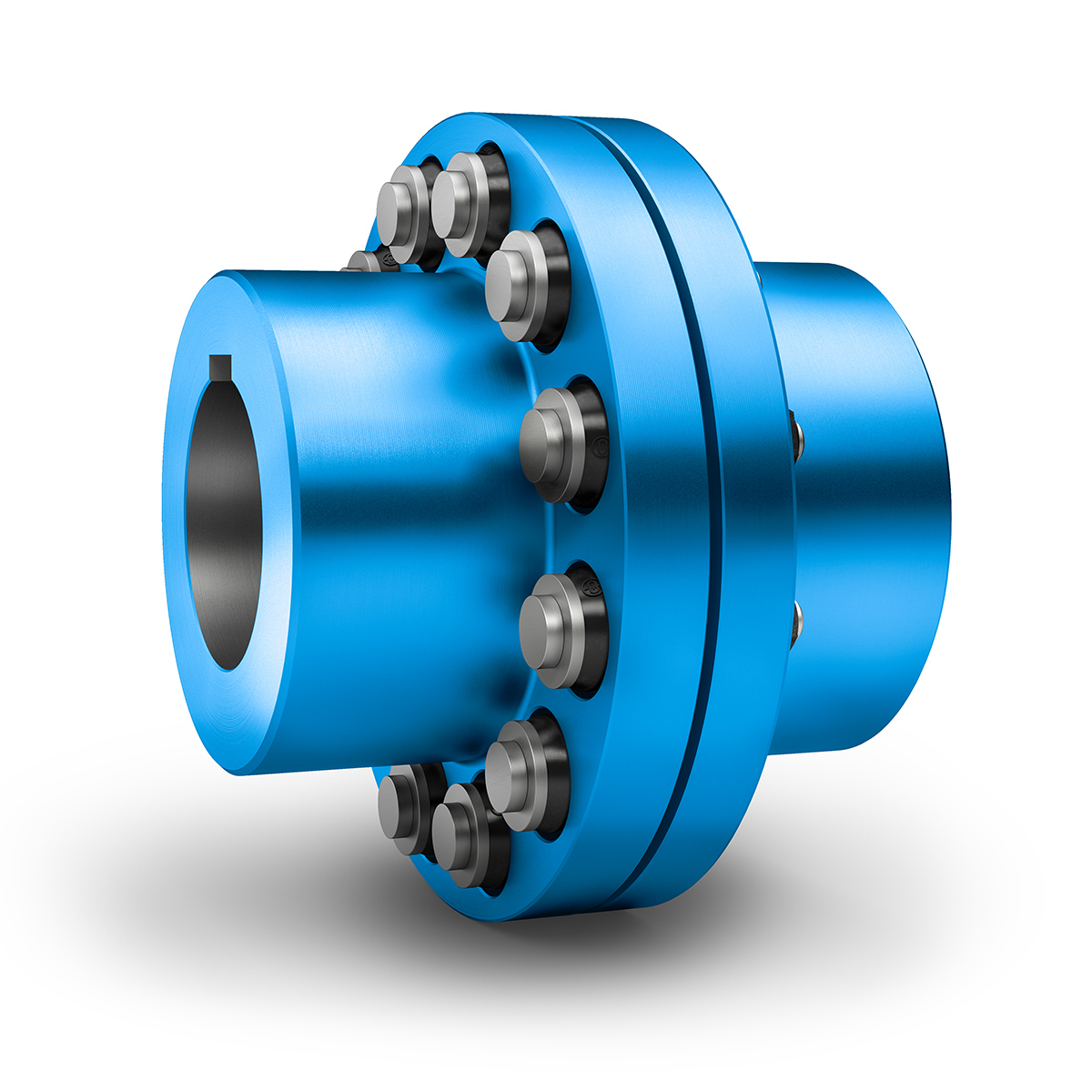

How Does a Pin Coupling Protect Connected Equipment from Shock Loads and Vibrations?

Pin couplings are designed to provide excellent protection to connected equipment from shock loads and vibrations, ensuring the smooth and reliable operation of the machinery. The unique features of pin couplings contribute to their ability to absorb and dampen shock loads and vibrations effectively:

- Flexibility: Pin couplings possess a certain degree of flexibility due to the presence of movable pins. When subjected to sudden shock loads or vibrations, the pins can flex and move slightly, absorbing the impact and preventing it from transmitting directly to the connected equipment. This flexibility helps in reducing stress and minimizing the risk of damage to the machinery.

- Torsional Compliance: The pin coupling’s design allows for a certain amount of torsional compliance. This means that when the connected shafts experience slight misalignments or angular displacements, the pin coupling can compensate for these variations without causing additional stress or vibration in the system. This feature ensures that the machinery remains in proper alignment even under dynamic conditions, reducing wear and tear.

- Damping Characteristics: The presence of movable pins introduces damping characteristics to the coupling. When vibrations occur in the system, the pins can dampen these oscillations, preventing resonance and the amplification of vibrations. This damping effect improves the overall stability and performance of the machinery.

- Strength and Resilience: High-quality pin couplings are constructed from durable materials with excellent fatigue resistance. This enables the coupling to withstand repeated shock loads and vibrations over an extended period without compromising its integrity. The strength and resilience of the pin coupling contribute to the protection of the connected equipment.

Overall, pin couplings are reliable and versatile components that can effectively protect connected equipment from shock loads and vibrations. Their flexibility, torsional compliance, damping characteristics, and robust construction make them suitable for various industrial applications where shock and vibration mitigation are essential for maintaining the health and longevity of machinery and equipment.

Impact of Pin Coupling on the Overall Reliability of Connected Equipment

A pin coupling plays a crucial role in enhancing the overall reliability and performance of connected equipment in various industrial applications. Its design and construction contribute to several factors that influence reliability:

1. Torque Transmission: Pin couplings efficiently transmit torque between the driving and driven shafts, ensuring smooth power transfer without slippage or loss. This consistent torque transmission helps maintain the stability and reliability of the system during operation.

2. Misalignment Compensation: Pin couplings are designed to accommodate small amounts of angular, parallel, and axial misalignment between shafts. By tolerating misalignment, the coupling reduces stress on connected equipment, bearings, and seals, thereby enhancing reliability and extending the service life of these components.

3. Shock and Vibration Absorption: In applications with dynamic loads, such as pumps, compressors, and heavy machinery, pin couplings help dampen shock and vibrations. By absorbing and reducing these impact forces, the coupling minimizes stress on the system and prevents premature component failure.

4. Simplified Maintenance: Pin couplings generally have a simple design, making them easy to install and maintain. The ease of maintenance ensures that the coupling can be regularly inspected, lubricated, and replaced when necessary, reducing downtime and increasing the overall reliability of the equipment.

5. Corrosion Resistance: Depending on the materials used, pin couplings can be highly resistant to corrosion, making them suitable for use in harsh or corrosive environments. This corrosion resistance prevents degradation of the coupling and its components, enhancing reliability and longevity.

6. Enhanced Durability: High-quality pin couplings are manufactured from robust materials and undergo precise machining processes. These attributes contribute to the coupling’s durability, allowing it to withstand heavy loads and harsh conditions over an extended period.

7. Balanced Design: The design of a pin coupling ensures that the load is evenly distributed between the driving and driven shafts. This balanced load distribution reduces stress concentrations, minimizes wear, and increases the reliability of connected equipment.

8. Compliance with Standards: Reputable pin coupling manufacturers ensure their products comply with industry standards and regulations. Meeting these standards ensures that the coupling is designed and manufactured to specific quality criteria, enhancing reliability and safety.

Overall, a well-selected and properly installed pin coupling can significantly improve the reliability and performance of connected equipment. It helps prevent unexpected failures, reduces downtime, and contributes to the overall efficiency of industrial processes.

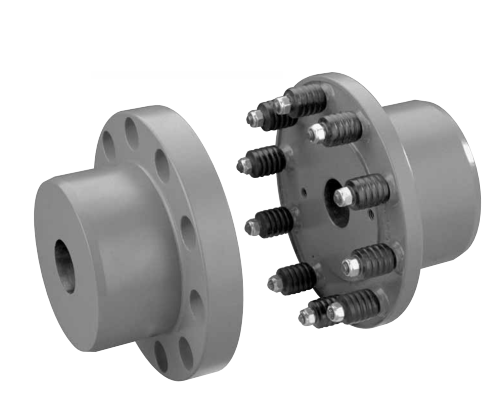

Can Pin Couplings Handle Misalignment Between Shafts?

Yes, pin couplings are designed to accommodate a certain degree of misalignment between shafts in rotating machinery. They are considered flexible couplings, which means they can provide some degree of angular, parallel, and axial misalignment capability.

Pin couplings typically consist of two hubs, each connected to a shaft, and a central sleeve with pins that transmit torque between the hubs. The pins allow for a limited range of movement, which helps to compensate for slight misalignments between the shafts.

The angular misalignment capacity of a pin coupling is achieved through the bending of the pins. When the shafts are misaligned at an angle, the pins on one side of the coupling experience bending while those on the opposite side are in tension. The pins are designed to withstand these bending and tension forces within their elastic limits, ensuring proper functioning and longevity of the coupling.

Similarly, the pins can accommodate parallel misalignment by sliding within the pin holes of the coupling’s central sleeve. This sliding action allows the hubs to move slightly relative to each other, compensating for any offset between the shafts.

However, it is essential to note that pin couplings have limitations in terms of the amount of misalignment they can handle. Excessive misalignment beyond their specified limits can lead to increased wear on the pins and other coupling components, reducing the coupling’s effectiveness and potentially causing premature failure.

While pin couplings are suitable for applications with moderate misalignment requirements, they may not be the best choice for applications with significant misalignment or where precise alignment is critical. In such cases, more flexible couplings like gear or elastomeric couplings may be more appropriate.

Overall, when considering the use of pin couplings, it is essential to carefully evaluate the specific misalignment requirements of the application and select a coupling that can adequately accommodate those misalignments while ensuring reliable and efficient power transmission.

editor by CX 2024-05-02