Product Description

Product Description

| Name | Outer hexagon oil plug bolt flange face plug throat dull M8-M48 | ||

| Process | Cold Forming | Transport Package | Plastic Bag, Carton Package, Pallet Package |

| Specialty | OEM, ODM | Production Capacity | 10 Million Per Month |

| Sample | Free Sample If in Store | QC Control | Inspect 30mins in Production and Before Delivery |

| Heat Treatment | thermalizer | QC Equipment | Salt Spray Machine, Hardness Testor, Caliper |

| Delivery time | 15-30 Days | Service | Quickly response |

| Application | Machinery, Chemical Industry, Environmental, Building | Brand | Linork |

| Applied Area | Building, Machinery, Auto, Car Wheel | Origin | HangZhou |

Detailed Photos

Company Profile

Packaging & Shipping

•If the quantity of order is not very big,we could send them to you by express delivery,such as TNT,DHL,UPS OR EMS etc.

•If order is big ,we will advise you use Air Shipping or Sea Shipping through your nominated forwarder agent.Our long-term cooperated agent also available.

FAQ

Q1: What are your main products?

A: At present, the company produces more than 1000 kinds of different fasteners, such as automobile standard parts, automobile non-standard parts, automobile lamps and fittings, automobile non-standard nuts (grade 8, 10, 12), automobile interior parts, low-voltage electrical components, stamping parts, high-strength screws (grade 8.8, 9.8, 10.9, 12.9), etc. And plastic parts, rubber rings, die casting more than 100 different products.

Q2: When will I know the price?

A: We usually offer within 12 hours, not more than 24 hours. In case of emergency, please contact us directly by phone or email.

Q3: Do you have enough capacity?

A: The current production capacity of the company is about 45,000 tons of steel, including 30,000 tons of wire and 15,000 tons of plate.

Q4: I’m not sure what screws to use, I need a little engineering help. Do you offer any help?

A: We have A complete engineering department that can provide you with the most suitable screws according to your product.

Q5: I need custom screws, but there are no screws listed on your website. What should I do?

A: Our professional engineers can design professional drawings according to your requirements, and can also produce according to the drawings you provide

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Brass |

|---|---|

| Type: | Round Head |

| Connection: | Common Bolt |

| Head Style: | Round |

| Standard: | DIN, ANSI, GB, JIS, BSW, GOST, Customized |

| Grade: | 12.9 |

| Samples: |

US$ 7/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

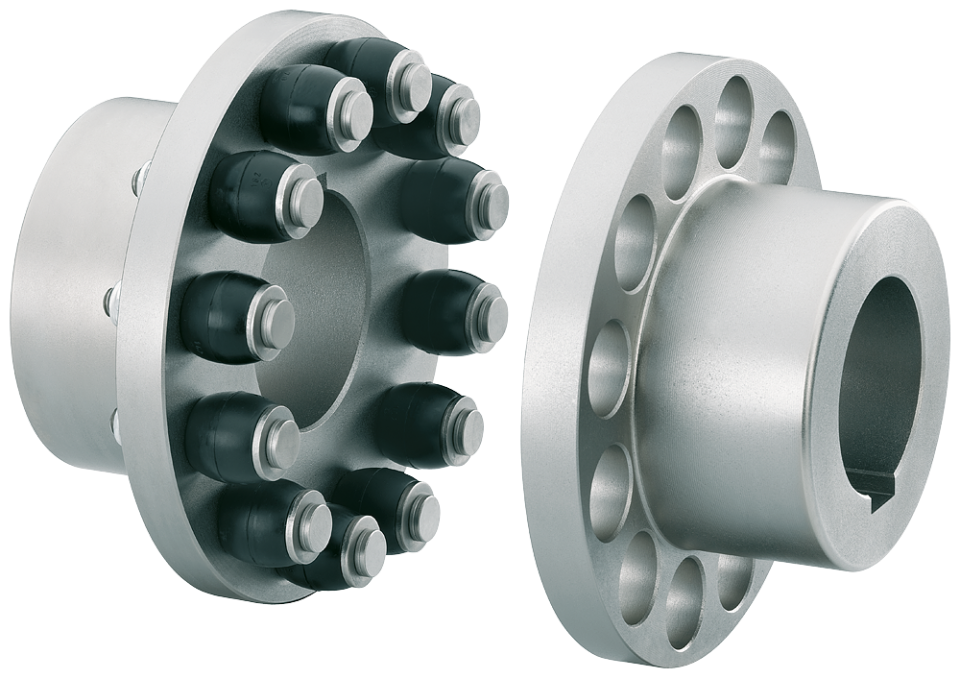

Can Pin Couplings Be Used in Both Horizontal and Vertical Shaft Arrangements?

Yes, pin couplings can be used in both horizontal and vertical shaft arrangements. These couplings are designed to accommodate angular misalignment, parallel misalignment, and axial movement, making them versatile for various shaft orientations.

In horizontal shaft arrangements, where the shafts are aligned on the same horizontal plane, pin couplings can efficiently transmit torque while allowing for flexibility to accommodate minor misalignments and shaft movements. The pins and flexible elements in the coupling enable angular displacement and radial flexibility, ensuring smooth power transmission even if the shafts are not perfectly aligned.

In vertical shaft arrangements, where the shafts are aligned on a vertical plane, pin couplings can also be used effectively. The coupling design allows for axial movement, which is crucial in vertical applications where the shafts may experience expansion or contraction due to thermal changes or other factors. The flexible nature of pin couplings allows them to handle these axial movements without compromising the coupling’s performance.

Whether in horizontal or vertical arrangements, pin couplings are commonly used in various industrial applications, including pumps, compressors, conveyors, and other rotating machinery. They are known for their simplicity, ease of installation, and ability to provide reliable power transmission while accommodating misalignment and shaft movement.

When using pin couplings in either arrangement, it is essential to ensure proper alignment and regular maintenance to maximize their performance and service life. Additionally, considering factors like torque requirements, operating conditions, and environmental considerations will help in selecting the appropriate pin coupling for a specific application.

Usage of Pin Couplings in Applications with Varying Operating Temperatures

Pin couplings are versatile and can be used in a wide range of operating conditions, including applications with varying temperatures. The performance of pin couplings at different temperature levels depends on the materials used in their construction and the specific design features. Here’s how pin couplings handle varying operating temperatures:

1. Material Selection: Pin couplings can be manufactured using different materials, including steel, stainless steel, alloy steel, and various heat-treated materials. The choice of material depends on the application requirements and the temperature range the coupling will be subjected to. Some materials are suitable for high-temperature applications, while others are more suitable for low-temperature conditions.

2. Heat Dissipation: The simple and open design of pin couplings allows for efficient heat dissipation. As the coupling operates, any heat generated due to friction or other factors can easily dissipate into the surrounding environment. This helps in maintaining a stable operating temperature and prevents overheating of the coupling and connected equipment.

3. Lubrication: Proper lubrication is essential for the smooth operation of pin couplings, especially in applications with high temperatures. Lubricants help reduce friction and wear between the mating surfaces, ensuring that the coupling functions optimally even in elevated temperature conditions.

4. Thermal Expansion Considerations: Pin couplings must be designed with thermal expansion in mind. When the operating temperature increases, the materials may expand, and the coupling should have sufficient clearance or play to accommodate this expansion without causing binding or interference.

5. Temperature Limits: While pin couplings can handle a wide range of temperatures, there are limits to the extremes they can tolerate. Excessive heat can lead to degradation of the coupling material, premature wear, or reduced performance. It’s essential to choose a pin coupling that is rated for the specific temperature range of the application.

6. Insulation: In certain cases, pin couplings may need additional insulation to protect against extreme temperature variations or to prevent heat transfer to sensitive components nearby. Insulation can be achieved using materials with low thermal conductivity or by incorporating insulating coatings or barriers.

When selecting a pin coupling for an application with varying operating temperatures, it’s crucial to consider the specific temperature range, the type of materials used in the coupling’s construction, and any additional factors that may impact its performance. Following the manufacturer’s guidelines and ensuring proper maintenance will help ensure the pin coupling operates effectively and reliably across the expected temperature range.

Advantages of Using Pin Couplings in Mechanical Systems

Pin couplings, also known as shear pin couplings, offer several advantages when used in mechanical systems. These advantages make them a popular choice for various industrial applications:

- 1. Overload Protection: Pin couplings are designed to provide overload protection to connected equipment. In case of excessive torque or sudden shock loads, the sacrificial pins will shear off, preventing damage to the shafts and other components.

- 2. Misalignment Tolerance: Pin couplings can accommodate a limited amount of angular misalignment between the shafts. This helps to compensate for minor misalignments and reduces the stress on the connected equipment.

- 3. Cost-Effective: The shear pins used in pin couplings are relatively inexpensive compared to other coupling components. In the event of a failure, replacing the damaged pins is a cost-effective solution, avoiding more significant repairs to the main equipment.

- 4. Easy Replacement: After shearing, the damaged pins can be quickly and easily replaced. This leads to reduced downtime and lower maintenance costs in the long run.

- 5. Versatility: Pin couplings are suitable for a wide range of applications, including pumps, compressors, fans, and other industrial machinery. Their ability to handle varying operating conditions makes them versatile in different environments.

- 6. Shock Load Absorption: Pin couplings can absorb and dissipate shock loads effectively. The shear pins act as a buffer, protecting the equipment from sudden impacts or overloads.

Despite their numerous advantages, it is essential to consider the limitations of pin couplings as well. They have lower torque capacities compared to some other coupling types, such as gear couplings or rigid couplings. Additionally, the need to replace shear pins after each failure may lead to more frequent maintenance requirements in applications with frequent overloads or misalignments.

In conclusion, pin couplings provide reliable torque transmission and safety features, making them a valuable component in various mechanical systems. Their ability to protect against overloads and accommodate misalignments makes them a practical choice in a wide range of industrial applications.

editor by CX 2024-04-23