Product Description

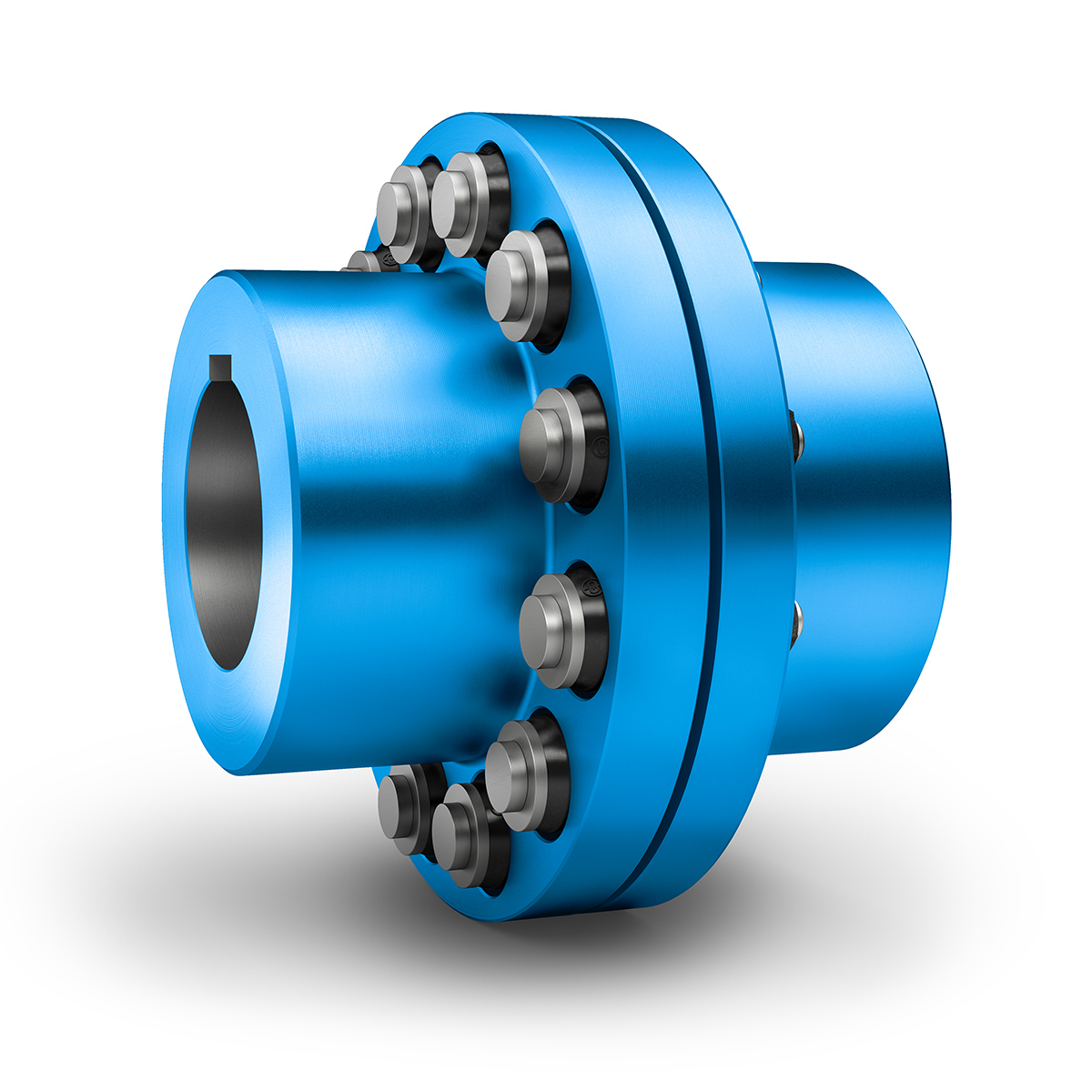

235 32K Excavator Coupling Machine Parts Track Pin Press Flexible Coupling

Basic information:

Model: 235 32K

Used on:Excavator, Air Compressor, Marine Machine

Packing: Plastic Bag, Carton

Coupling Type: Coupling Inserts

Material: Rubber, Iron

Payment Methods: Bank Transfer, Western Union, Money Gram, Credit

Coupling Structure: Helical Coupling

Supply Ability: 3000PCS Per Week

After-sales Service: Online Support

Coupling Structure: Helical Coupling

Products Parts:

| Pos. | Part No | Qty | Parts name |

| 1. | 9K-3115 | [1] | HEAD |

| 2. | 3P-1388 | LOCKWIRE 7.62 dm(30 in.) | |

| 3. | 2B-2955 | [4] | BOLT |

| 4. | 5K-1787 | [1] | SEAL |

| 5. | 7J-3322 | [1] | SEAL |

| 6. | 9K-3307 | [1] | PISTON |

| 7. | 9K-3304 | [1] | SEAL |

| 8. | 9K-9716 | [1] | HOUSING |

| 9. | 8S-2332 | [4] | BOLT |

| 10. | 9K-3148 | [1] | SHAFT |

| 11. | 8K-0507 | [4] | DISC |

| 12. | 8K-0509 | [5] | PLATE |

| 13. | 9M-5571 | [1] | SEAL |

| 14. | 9K-9715 | [1] | ADAPTER ASSEM. |

| 15. | 4D-0672 | [2] | DOWEL |

| 16. | 5J-2383 | [1] | SEAL |

| 17. | 8K-0508 | [2] | SPRING |

| 18. | 8K-571 | [2] | RETAINER |

| 19. | 1D-4623 | [4] | BOLT |

| 5H-1504 | [4] | WASHER | |

| 20. | 9K-3145 | [4] | BOLT |

| 21. | 9K-3305 | [1] | WASHER |

| 22. | 6B-3645 | [1] | SNAP RING |

| 23. | 4F-8824 | [1] | SEAL |

| 24. | 8K-2004 | [1] | SHAFT |

About us:

specialized in:

couplings, rubber mounts, gera parts, hydraulic seals and seal kits for hydraulic hammers, rock breakers, hydraulic excavators,wheel loaders, and JCB badkhoe loaders.

And, Our company also supply:

Engine parts, hydraulic piston pump and hydraulic travel motor, Swing motor assembly and hydraulic component parts, electric parts, etc. Hydraulic hammer breaker parts with piston, cylinder, chisel, through bolt, side bolt, top bush, front head bushing,accumlator, valve, etc.

We always try our best for all our customers and make it better and better. Welcome!

Products Show:

FAQ

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Online Support |

|---|---|

| Warranty: | Six Months |

| Type: | Coupling |

| Application: | Excavator |

| Certification: | CE |

| Condition: | New |

| Customization: |

Available

| Customized Request |

|---|

Can Pin Couplings Accommodate High Torque and High-Speed Applications?

Pin couplings are versatile and robust, making them suitable for a wide range of applications, including those involving high torque and high-speed requirements. However, the specific design and construction of the pin coupling will determine its capacity to handle such demanding conditions.

The ability of a pin coupling to accommodate high torque depends on factors such as the material used, the size and number of pins, and the overall design. High-quality pin couplings are often made from strong and durable materials like alloy steel, which allows them to withstand significant torque loads without failure or deformation.

Similarly, the capability of a pin coupling to handle high speeds depends on factors such as the balance of the coupling and the precise manufacturing of the pins and hubs. Properly balanced pin couplings can operate at higher speeds without generating excessive vibration or causing premature wear.

When selecting a pin coupling for high torque and high-speed applications, it is essential to consider the following:

- Design and Construction: Opt for pin couplings with a robust and well-engineered design to handle the expected torque and speed requirements.

- Material: Choose pin couplings made from high-quality materials known for their strength and fatigue resistance.

- Size: Select an appropriate size of pin coupling that can accommodate the torque and speed expected in the application.

- Manufacturer’s Ratings: Refer to the manufacturer’s specifications and torque-speed curves to ensure the coupling meets the desired performance criteria.

By carefully considering these factors and choosing a pin coupling designed for high torque and high-speed applications, you can ensure reliable and efficient power transmission in demanding industrial settings.

Impact of Pin Coupling on the Overall Reliability of Connected Equipment

A pin coupling plays a crucial role in enhancing the overall reliability and performance of connected equipment in various industrial applications. Its design and construction contribute to several factors that influence reliability:

1. Torque Transmission: Pin couplings efficiently transmit torque between the driving and driven shafts, ensuring smooth power transfer without slippage or loss. This consistent torque transmission helps maintain the stability and reliability of the system during operation.

2. Misalignment Compensation: Pin couplings are designed to accommodate small amounts of angular, parallel, and axial misalignment between shafts. By tolerating misalignment, the coupling reduces stress on connected equipment, bearings, and seals, thereby enhancing reliability and extending the service life of these components.

3. Shock and Vibration Absorption: In applications with dynamic loads, such as pumps, compressors, and heavy machinery, pin couplings help dampen shock and vibrations. By absorbing and reducing these impact forces, the coupling minimizes stress on the system and prevents premature component failure.

4. Simplified Maintenance: Pin couplings generally have a simple design, making them easy to install and maintain. The ease of maintenance ensures that the coupling can be regularly inspected, lubricated, and replaced when necessary, reducing downtime and increasing the overall reliability of the equipment.

5. Corrosion Resistance: Depending on the materials used, pin couplings can be highly resistant to corrosion, making them suitable for use in harsh or corrosive environments. This corrosion resistance prevents degradation of the coupling and its components, enhancing reliability and longevity.

6. Enhanced Durability: High-quality pin couplings are manufactured from robust materials and undergo precise machining processes. These attributes contribute to the coupling’s durability, allowing it to withstand heavy loads and harsh conditions over an extended period.

7. Balanced Design: The design of a pin coupling ensures that the load is evenly distributed between the driving and driven shafts. This balanced load distribution reduces stress concentrations, minimizes wear, and increases the reliability of connected equipment.

8. Compliance with Standards: Reputable pin coupling manufacturers ensure their products comply with industry standards and regulations. Meeting these standards ensures that the coupling is designed and manufactured to specific quality criteria, enhancing reliability and safety.

Overall, a well-selected and properly installed pin coupling can significantly improve the reliability and performance of connected equipment. It helps prevent unexpected failures, reduces downtime, and contributes to the overall efficiency of industrial processes.

Types of Pin Coupling Designs

Pin couplings, also known as shear pin couplings, come in various designs to suit different application requirements. The main types of pin coupling designs are as follows:

- 1. Single Pin Coupling: In this design, a single shear pin is used to connect the two shafts. The pin is placed in a hole that runs through both coupling halves. Under excessive torque or shock loads, the pin shears off, disconnecting the shafts and protecting the equipment from damage. Single pin couplings are commonly used in light to moderate-duty applications.

- 2. Double Pin Coupling: Double pin couplings use two shear pins that are positioned 180 degrees apart. This design provides increased torque capacity and improved balance compared to the single pin design. Double pin couplings are suitable for applications with higher torque requirements.

- 3. Triangular Pin Coupling: Triangular pin couplings use three pins arranged in a triangular pattern around the circumference of the coupling. This design offers even higher torque capacity and improved torsional stiffness. Triangular pin couplings are ideal for heavy-duty applications where higher torque and misalignment tolerance are essential.

- 4. Splined Pin Coupling: Splined pin couplings use splines instead of solid pins to transmit torque between the shafts. The splines provide a more secure connection and better torque transmission compared to solid pins. Splined pin couplings are commonly used in precision motion control applications.

- 5. Taper Pin Coupling: Taper pin couplings use tapered pins that wedge tightly into matching tapered holes in the coupling halves. This design offers excellent torque transmission and alignment capabilities. Taper pin couplings are often used in heavy machinery and power transmission systems.

Each type of pin coupling design has its advantages and limitations, and the selection depends on factors such as the application’s torque requirements, misalignment tolerance, and environmental conditions. It is essential to choose the right type of pin coupling to ensure optimal performance, reliability, and safety in the mechanical system.

editor by CX 2024-05-02