Product Description

Product Description

| BASIC INFORMATION | |

| ITEM | NH Coupling |

| SIZE | 1.5″/2″/2.5″/3″/4″/5″/6″ |

| TECH. | Forged |

| W.PRESSURE | 2.5MPa(365PSI) |

| T. PRESSURE | 4.0MPa(580PSI) |

| MATERIAL | Aluminum Alloy |

| COLOUR | Sliver/Golden/Black/Customized |

| BRAND | TOKAI XIHU (WEST LAKE) DIS.TA/ OEM |

| SERVICE | OEM/ODM |

| FINISH | Anodizing/Hard Anodizing |

| HISTORY | 22years manufacturing experiences of fire fighting equipments |

| HS CODE | 8481809000 |

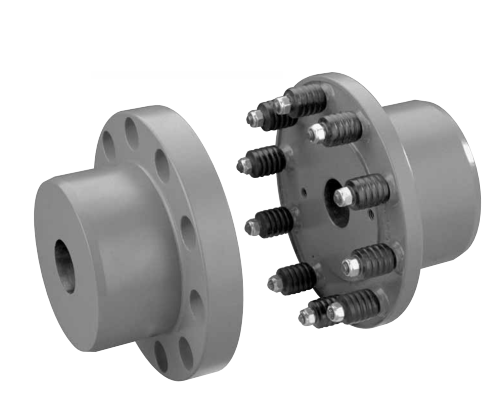

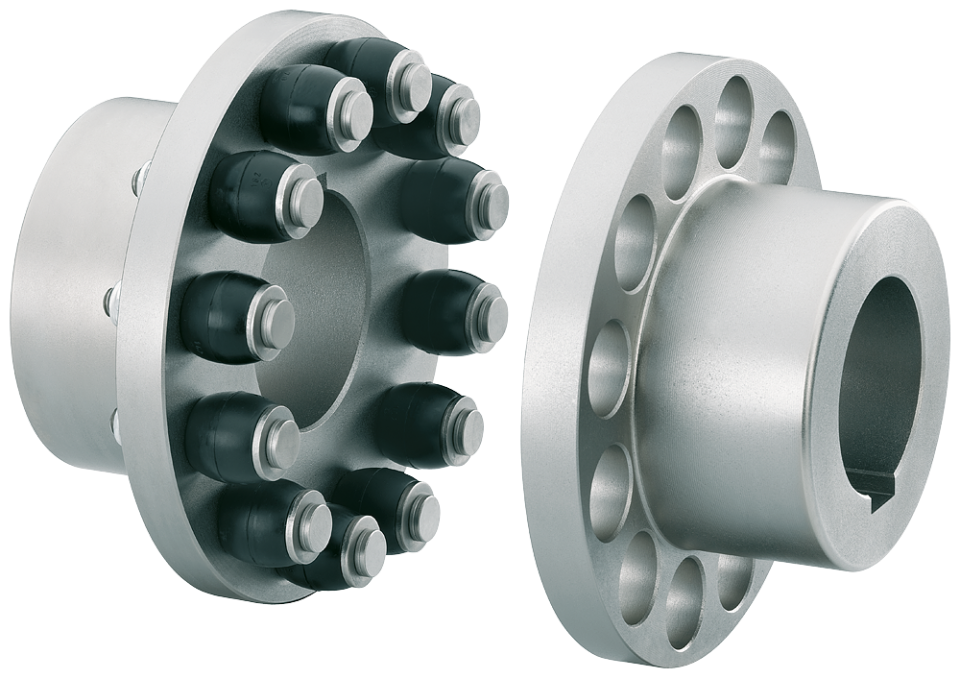

Detailed Photos

Packaging & Shipping

Company Profile

TOKAI XIHU (WEST LAKE) DIS.TA is specialized in designing and manufacturing fire fighting equipment mainly including fire hose couplings and fittings, nozzles, fire vehicle equipment and fire hose crimping machine. We employed CNC lathe, CNC turning composite center, CNC machining center, forging equipment, heat treating facility and the latest testing equipment to improve dimensional accuracy and quality management. Given more than 20years of development, we not only have broadened the company’s product line but also have developed our capability to meet our customers’ specific requirements and offer products or services that give added value. We have passed the ISO9001:2015 Quality Management System Evaluation and got the certification of CCC. At present, our products are mainly exported to Japan, the United States, Germany, South Korea, ZheJiang , Indonesia, Thailand, Dubai and other global markets, which are highly praised by customers. In domestic market, high-end fire hose factories, fire vehicle manufacturers and the national fire team are our important strategic partners.

Adhere to the idea of forward-looking innovation, outstanding excellence, continuous improvement and sustainable management, we provide best service to clients. The most important purpose of our company is to ensure that our products have excellent quality, on time delivery with competitive price. We will take it as our duty to create most valuable brand in high-end fire hose couplings. Let’s join hands and work together to build a prosperous future!

Certifications

Our Advantages

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Certification: | CCCF, CCC, ISO9001 |

|---|---|

| Surface Treatment: | Anodizing/Hard Anodizing |

| Material: | Aluminum Alloy |

| Tech.: | Forged |

| W.Pressure: | 2.5MPa(365psi) |

| Color: | Silver/Golden/Black |

| Samples: |

US$ 25/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What Are the Maintenance Requirements for Pin Couplings?

Pin couplings are known for their simplicity and ease of maintenance. Regular maintenance helps ensure the longevity and optimal performance of pin couplings in various mechanical systems. Here are the key maintenance requirements for pin couplings:

- Lubrication: Most pin couplings require periodic lubrication to reduce friction between the pins and the coupling hubs. Lubrication helps prevent wear and corrosion, ensuring smooth operation.

- Inspection: Regular visual inspections are essential to identify any signs of wear, misalignment, or damage. Inspecting the pins, coupling hubs, and surrounding components can help detect potential issues early on.

- Torque Check: It is crucial to periodically check and retighten the bolts or screws that secure the coupling to the shafts. Loose fasteners can lead to misalignment and coupling failure.

- Alignment: Proper shaft alignment is critical for the effective functioning of pin couplings. Regularly check and adjust the alignment if necessary to minimize wear and vibrations.

- Environmental Protection: In harsh environments or corrosive conditions, take measures to protect the pin coupling from contaminants or chemicals that could cause damage.

- Replacement of Worn Components: When any of the coupling components, such as pins or hubs, show signs of significant wear, they should be replaced promptly to prevent further damage.

It is important to follow the manufacturer’s maintenance guidelines and recommendations for the specific type of pin coupling used in the application. Regular maintenance not only ensures the smooth operation of the coupling but also helps prevent unexpected breakdowns and reduces the risk of costly downtime. Proper maintenance can extend the service life of pin couplings and contribute to the overall reliability of the connected equipment.

What Industries Commonly Use Pin Couplings for Power Transmission?

Pin couplings are widely used in various industries for power transmission due to their ability to accommodate misalignment and provide reliable torque transmission. Some of the industries where pin couplings are commonly employed include:

- 1. Manufacturing: In manufacturing processes, pin couplings are used in conveyor systems, mixers, agitators, and other machinery to transfer power between motors and driven equipment.

- 2. Pulp and Paper: The pulp and paper industry uses pin couplings in machinery such as pumps, fans, and rotary kilns for continuous power transmission.

- 3. Chemical and Petrochemical: Pin couplings find applications in chemical processing plants, refineries, and petrochemical facilities for various rotating equipment.

- 4. Water and Wastewater: Pin couplings are used in water treatment facilities, pumps, and blowers to transfer power efficiently.

- 5. Steel and Metal Processing: Steel mills and metal processing plants utilize pin couplings in rolling mills, extruders, and other equipment.

- 6. Food and Beverage: Pin couplings are employed in food processing machinery, packaging equipment, and conveyor systems.

- 7. Mining and Quarrying: The mining industry uses pin couplings in crushers, conveyor belts, and various mineral processing equipment.

- 8. Oil and Gas: Pin couplings are used in the oil and gas sector for pumps, compressors, and drilling equipment.

- 9. Power Generation: In power plants, pin couplings are used in turbines, generators, and other power transmission systems.

- 10. Construction and Heavy Equipment: Pin couplings find applications in construction machinery, earthmoving equipment, and other heavy-duty machinery.

- 11. Agriculture: In agricultural machinery, pin couplings are used in tractors, irrigation systems, and grain processing equipment.

These are just some examples of the industries where pin couplings are commonly used. Pin couplings offer versatility, ease of installation, and reliability, making them suitable for a wide range of applications in different sectors where power transmission is essential.

Limitations and Disadvantages of Using Pin Couplings

While pin couplings offer various advantages and are suitable for many applications, they also have some limitations and disadvantages to consider:

- Misalignment Restrictions: Pin couplings can accommodate a certain degree of misalignment, but excessive misalignment can lead to increased wear and stress on the coupling components. They are not as effective at handling large angular or parallel misalignments compared to other flexible couplings like gear or elastomeric couplings.

- Less Damping Capacity: Pin couplings have limited damping capacity, which means they may not effectively absorb and reduce vibrations in the system. In applications where vibration damping is critical, elastomeric or flexible couplings may be more suitable.

- Noisy Operation: The rigid nature of pin couplings can lead to increased noise during operation, especially at high speeds or in applications with significant misalignment. This noise can be a concern in environments where noise levels need to be minimized.

- Higher Maintenance: Compared to maintenance-free couplings like certain types of elastomeric couplings, pin couplings may require more frequent inspection and maintenance. The pins and other components may experience wear over time and need replacement.

- Environmental Limitations: Some pin couplings may not be suitable for use in corrosive or high-temperature environments, depending on the materials used. Stainless steel or other corrosion-resistant materials can help mitigate this limitation.

- Size and Weight: In certain applications, the size and weight of pin couplings may be larger and heavier compared to other types of couplings. This can be a consideration in applications where weight is a concern or space is limited.

Despite these limitations, pin couplings remain a popular choice for many applications where their advantages, such as simplicity, durability, and cost-effectiveness, outweigh their disadvantages. It is crucial to carefully assess the specific requirements of the application and consider factors like misalignment, vibration, maintenance needs, and environmental conditions when selecting a coupling type.

editor by CX 2024-04-30