With detailed requirments, we can also develop your special designed product. a specialized supplier of a full range of chains, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant

- Type:

-

Straight bevel gear

- Teeth:

-

Grinding or not

- Module:

-

0.4-20

-

SHAFT SURFACE QUALITY To function effectively and provide satisfactory life, oil seals must have a thin oil film between the seal lip and mating shaft journal. This condition, known as hydrodynamic lubrication, needs shaft surfaces that are not perfectly smooth but have microscopic pockets to help maintain the lubricant film. Although plunge grinding is most widely used to finish seal journals, the resulting surface is not ideal from this standpoint. Other finishing methods, such as shot peening and liquid honing, provide a matte-type finish which is generally more effective than a plungeground surface. However, even these methods often leave raised, sharp corners that separate the resulting microscopic indentations, again providing potential starting points for leaks.

- Service:

-

Reply in 12 hours at any time

- Normal material:

-

20CrMnTi

- Material2:

-

Steel, Stainless steel, POM etc.

- Heat treatment:

-

Teeth hardened HRC55-63

Supply Ability

- Supply Ability:

- 5000 Piece/Pieces per Month

Packaging & Delivery

- Packaging Details

- Antirust oil + Paper bag + Wooden case

- Port

- Ningbo, Shanghai or as request

-

Lead Time

: -

Quantity(Bags) 1 – 200 201 – 500 501 – 2000 >2000 Est. Time(days) 30 40 60 To be negotiated

Online Customization

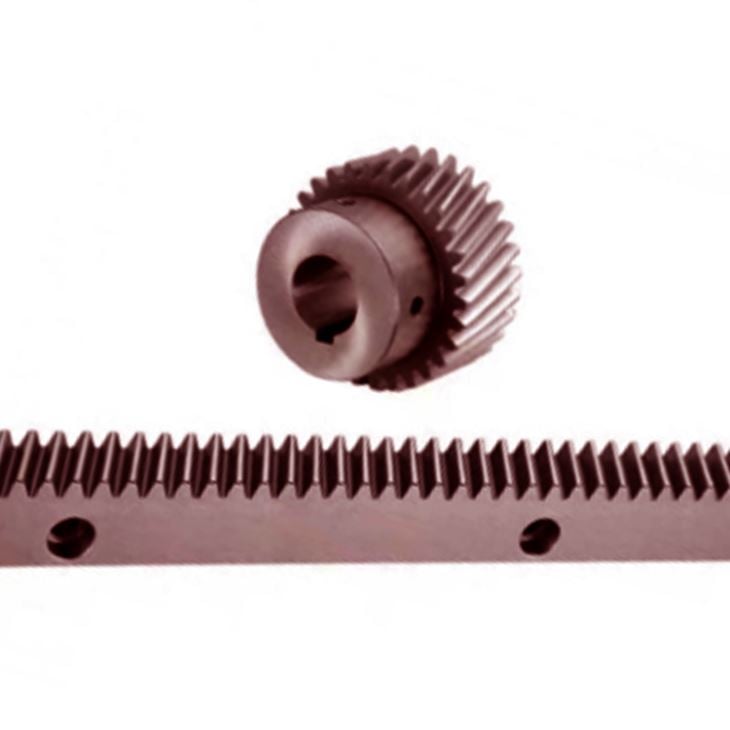

China manufacturer high precision Spiral Hypoid Bevel Gear

Spiral bevel gears

Our spiral bevel gears are welcomed by many customers for its stable high quality and competitive price.

The producing character of JH spiral bevel gears:

1. Gear size: the biggest diameter is 1800mm;

2. Material: Most common steel is high strength steel 20CrMnTi. Others can be steel C45, stainless steel, high strength steel, copper, aluminium, plastic, POM etc;

3. Spiral bevel Gear module: 0.3-20 (pitch from 0.942-62.80mm, DP 1.27-85);

4. Surface: zinc (galvanized), black, chromium plating, nickel plating, quenching and tempering etc.

5. Quality: stable and high, grade 7 for without teeth grinding, grade 6 after teeth grinding, grade 5 for precise grinding.

Prices for above quality are very competitive for us.

6. Heat treatment: teeth can be hardened to HRC 55-63.

The quality character of JH spiral bevel gears:

1. Stable transmission and low noise;

2. Effectively avoid normal tolerance based on high precision;

3. The teeth can be ground to grade 6 and grade 5 quality;

4. The bore will be polished to smooth and high precision;

5. The price is competitive even the quality is high.

| Facilities |

Machining center, Gleason machines, CNC gear hobbing machine, CNC gear shaper, CNC gear grinding machine, CNC turning machine, CNC milling machine, Y58200 CNC large gear rack shaper, Y58125A gear rack shaper, England gear rack shaper, and Russia gear rack shaper, |

| Gear types |

Helical gears (more and more widely used for its stable transimission); Spur gears; Hub gears; Bevel gears; Bevel spiral gears; Gear ring; etc. |

| Material |

Steel: C45, Q235, 40Cr, 20CrMnTi, etc. Stainless steel: 301, The company was certified by ISO9001:2008 Quality Management System.201, 304, 316 etc. Brass: H59 H68 H80 H90 etc. Aluminium: 6082, 6061, A380 etc. Aluminium alloy: 6061, 5083, 7050, etc. More: PA6, PA66, POM, ABS etc. |

| Surface | Polishing; Plating; Galvanized; Blacken; chromium plating, nickel plating; painting etc. |

Full experience on Spiral bevel gears

Our Services

1. Delivery time: 15-25 days for small order;

30-45 days for big order. (Never delayed till now)

Can be discussed for more urgent order.

2. Response time: usually in 1 hour and in 12 hours even in our holidays.

3. Process feedback: Photos or vedios will be sent for 2-3 times to inform you the producing situation.

4. Test report: The test report can be offered as request.

5. Payment terms: T/T, L/C, D/P, D/A, O/A, M/T, D/D etc.

6. Trade terms: FOB, CFR, CIF, FCA, CPT, CIP, DDU, DDP etc.

Company Information

FAQ

Q: Manufacturer?

A: Yes. Since 2004 only focus on producing high quality gears and racks.

Q: Cat 3 Point Hitch How do I operate the PTO on my tractor? Prior to running the PTO, you will need your tractor to reach the starting RPM (revolutions per minute). Once the starting RPM has been reached you can begin operating the PTO.Response time?

A: Reply very soon, and reply in 12 hours at any time.

Our technicians are always together with salesmen, so your any questions can be replied very soon.

Q: Price?

A: Drawings are more appriated for quotation. Or, please inform us your request, we will make drawings for your check.

Q: Delivery time?

A: 15-25 days for small order (<200 pcs), 30-45 days for large order.

Orders never be delayed, the products will be sent on time as agreement.

Q: Quality?

A: Middle and high quality is more competitive.

Q: Payment terms?

A: T/T for less than US$20,000 order, and L/C, D/P, D/A, O/A, M/T, D/D etc. for large orders.

Q: Trade terms?

A: FOB, CFR, CIF, FCA, CPT, CIP, DDU, DDP etc. are all accepted.

Hot related products

Contact us